Used by many industries and sectors, anti-static mats and flooring are important for protecting sensitive electronic components from damage caused by static electricity. While it’s easy to understand the basics of how anti-static floor mats work, many people don't know how they provide a safe and reliable way to prevent static electricity from damaging delicate electrical components. So what is anti-static matting? This article will explain what anti-static mats are, how they work, and why you need them in your business.

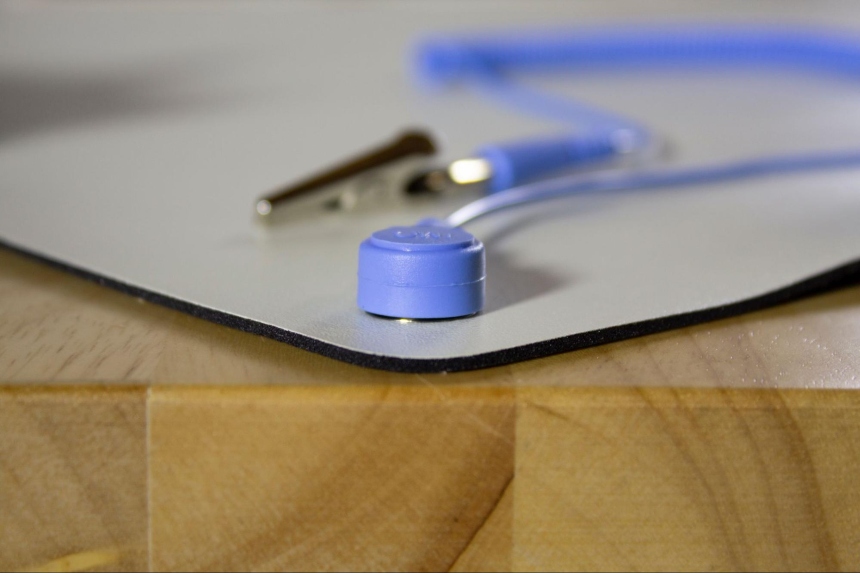

Anti-static floor matting is a type of matting designed to dispel electrostatic discharge (ESD) and protect sensitive electronic components and people from being damaged by the transfer of electrical static. This type of matting can be used in various commercial settings, including offices, manufacturing facilities, and laboratories.

The most common anti-static matting is made from rubber materials, helping discharge the electricity before reaching nearby objects or people. Anti-static floor matting and benchtop matting are essential for protecting delicate electronics from damage due to static electricity build-up, and it’s difficult to prevent it without this type of matting.

Anti-static matting is an indispensable product for any workspace environment. But alongside the obvious benefits, here are a few others that anti-static mats can bring:

The primary purpose of anti-static matting is to prevent or reduce damage from electrostatic discharge to electrical components that are ESD-sensitive. There are several types of anti-static matting for this, including conductive, dissipative, and static-dissipative.

Conductive matting is made of materials that conduct electricity, such as carbon-loaded rubber and can be used for bench top or floor use to remove static and ground a charge quickly.

Dissipative matting is made of materials, such as rubber or vinyl with added carbon or other conductive materials that release or bleed off electrical charge more slowly.

Static-dissipative matting is a combination of conductive and dissipative matting, designed to quickly release an electrical charge while also providing a good level of conductivity.

Anti-static matting is a shield that protects people and sensitive electronic equipment by providing a path for the ESD to be released safely. When you walk on or come into contact with anti-static matting, any static electricity that builds up on your body or clothing is safely discharged through the matting, preventing damage or interference to sensitive electronic equipment.

It does this by slowing down the flow of positive static charge, cancelling the harmful static electricity, and directing the charge into the grounded mat for electrical insulation and away from the electronic components being worked on.

How well this process works depends on the type of material the anti-static matting is made from. Most matting uses materials that are either conductive, dissipative, or a combination of both (static-dissipative), as detailed above. But the level of electrical resistance is crucial for the matting to work effectively.

Electrical resistance in anti-static matting is vital to providing the safest way for the electrical charge to dissipate. It can be achieved using matting materials with a specific resistance value, measured in Ohms (Ω).

If matting has a low grounding resistance, static will transfer to the mat, causing an electrostatic discharge and spark that will damage electronic equipment. If matting has a high grounding resistance, static transfers more slowly, and items on the mat won’t lose their charge sufficiently.

To prevent static electricity buildup and damage, floor or bench anti-static matting is used in different industries, settings, and applications where the risk of static is high. Some of the most common settings and applications include:

Anti-static matting is used to assemble and repair electronic devices such as computers, smartphones, and other electronic devices and machinery.

Anti-static matting is essential to cleanrooms and other controlled environments in preventing contamination and protecting sensitive electronic equipment.

Laboratories and research facilities will use anti-static matting to protect delicate scientific equipment and experiments.

In the pharmaceutical industry, anti-static matting protects equipment and ingredients from static electricity damage, which can cause contamination.

The aerospace and aviation industries use anti-static matting to protect sensitive electronic equipment and avionics. The automotive industry also uses it to overcome static issues in the production of thermoplastics, vacuum forming, and extruded parts.

When figuring out what sort of anti-static floor or bench matting you need, consider your work environment and the specific application it will be used for. Choosing the correct type means you and your electrical components get the proper protection against static electricity. Here are some of the key factors to consider:

Your mat's electrical resistance is a measure of how well it will conduct electricity for your needs. Look at conductive and dissipative matting to ensure it gives adequate protection.

Most anti-static floor mats are hard-wearing and durable for protection against wear and tear, while many have anti-slip properties too. Check its resistance to chemicals if this is necessary. If prolonged standing is required, consider matting with anti-fatigue qualities as well.

Consider the size and shape of your anti-static matting. While mats come in standard sizes, custom shapes and sizes are often available to fit the workspace and equipment.

It’s important to consider industry compliance for any anti-static matting. Matting materials must meet EOS/ESD-S4 regulations and comply with IEC 61340-5-1 standards.

Anti-static mats might not look very different from standard anti-slip or anti-fatigue mats, but they do a very specific job and should give you years of good service – provided they’re well looked after and maintained. Dust, dirt, and debris can accumulate on the mat’s surface over time, especially floor matting, which could become less effective. The simple answer is to clean each mat regularly by vacuuming floor matting to remove loose dirt or debris before using a non-aggressive, alcohol-free cleaner that can control static electricity.

Anti-static matting is crucial for protecting electronic equipment from static electricity, which can cause damage and disrupt operations, and improving employee safety by reducing the risk of electric shock.

MatsDirect UK offers a range of anti-static matting options, making it easier for you to find the right one for your application needs. For more information on anti-static flooring or bench mats, contact MatsDirect UK today by sending us a message, calling the team on 0161 797 6785, or emailing us at sales@matsdirect.co.uk, and we’ll help you make an informed decision.

MatsDirect UK Ltd is fully ISO 9001:2015 (Quality Management System) accredited, which means we have demonstrated our ability to consistently provide products to the industry’s highest quality and standards.

Now, how’s that for peace of mind?

Website designed by Highpoint Media