Electrical insulation is a vital component in the safe operation of any live electrical currents. It plays a crucial role in preventing electrical shocks, fires, and other hazards by providing an effective barrier between live electrical systems, switchboards, and grounded surfaces. In this article, we’ll answer the question of ‘what is electrical insulation?’, discuss its importance, and expand on the various materials and applications of insulation materials.

Electrical insulation refers to any materials used to prevent the flow of high or low-voltage electrical current running through it. These materials, such as rubber, ceramic, plastic, and fibreglass, act as a protective cover for conductive (live) parts like wires, components, and switchboards, shielding people against any electrical shock and systems from short circuits. Electrical systems would be much less reliable without proper insulation and more dangerous to operate, maintain, or repair. Any type of electrical insulation must withstand high temperatures without breaking down or becoming electrically conductive. But all electrical insulation is essential in ensuring electrical systems and components are safe and work efficiently.

Acting as the only protection between a person and serious injury or death, the role of electrical insulation in preventing accidents can’t be overstated. Without proper insulation, high or low-voltage live current can flow through unintended paths, leading to electrical fires and life-threatening shocks. Electrical insulation helps to protect both the electrical system or equipment and the people working with it. For example, in an industrial environment, correct electrical insulation safety matting for machinery and equipment helps to protect staff from electric shock – which can cause breathing difficulties, muscle spasms, and the heart to stop beating properly – and burns when using or maintaining it.

In addition to providing protection against these issues and preventing other workplace accidents, insulation also helps improve electrical systems' efficiency. Insulation can reduce the amount of electrical energy lost as heat, providing better energy efficiency and much-needed cost savings where large amounts of energy are used.

Electrical insulation significantly contributes to all electrical systems' safe and efficient operation, protecting equipment and employees from accidents. Of course, regular inspection and maintenance of all electrical insulation is vital, so it remains in good condition and can provide the necessary level of protection.

Electrical insulation is an absolute must to protect your business and your staff. In the earliest days of electrical insulation readily available materials such as cloth and rubber were the primary means of insulation.

These materials would be effective for low voltage applications, but they had limitations in terms of durability and resistance towards higher temperatures and voltages.

As the demand for electricity grew and systems became more powerful the need for more advanced insulation became an absolute must.

This led to the development of polymers in the early twentieth century. Polymers have versatile properties, and they provide far better thermal stability, higher electrical resistance and also greater durability.

Material such as PVC and PE which stand for polyvinyl chloride and polyethylene respectively helped to revolutionise electrical insulation especially in household wiring and electronic devices.

Another leap in the evolution of electrical insulation was the introduction of ceramic and glass materials. Known for their exceptional heat and wear resistance, these materials found their place in high-voltage and high-temperature applications. Ceramics, in particular, became integral in insulating spark plugs, electrical towers, and other components exposed to extreme conditions.

The next leap in the evolution of electrical insulation was the introduction of ceramic and glass materials. These are known for their exceptional heat and wear resistance. Ceramics in particular started to become integral in insulating spark plugs, electrical towers and other components.

Integrating Safety with Electrical Insulation Mats

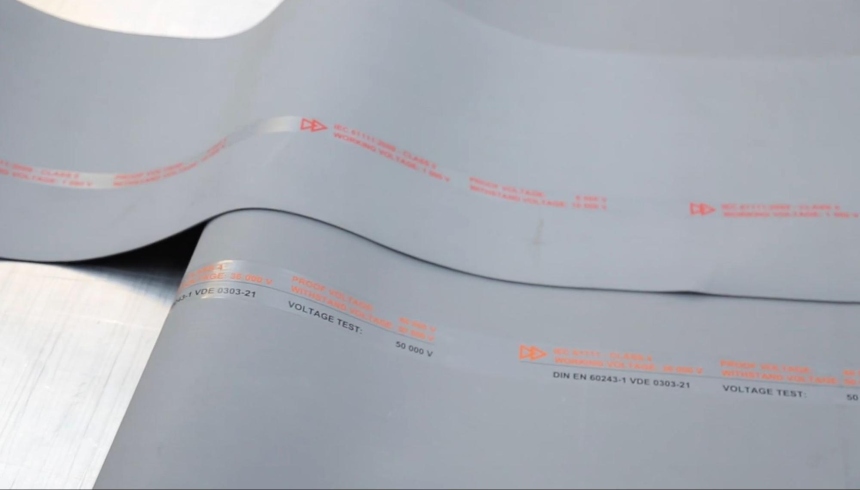

In parallel with the advancements in insulation materials there has also been a significant progress in the development safety equipment for electrical applications. A critical component is electrical safety mats. These mats are designed to protect individuals working in close proximity to high-voltage equipment.

Electrical safety mats, often made from rubber or PVC provide a protective barrier between the person and the ground. This is essential in preventing electric shocks, especially in areas where workers are exposed to live electrical currents.

The mats work by providing a high resistance, this ensures that the electrical current does not easily pass through a person’s body to the ground. This is of course critical in environments like power plants, electrical switchboards and industrial settings where the risk of electrical accidents is high.

At Mats Direct we ensure that these mats are designed with durability and safety in mind. You will get electrical safety mats that are able to withstand extreme conditions while also providing a stable and nonconductive surface, many of our mats often feature anti-slip surfaces for additional safety ensuring that workers can have a secure footing even in busy or wet conditions.

As technology advances in the field of electrical safety the importance of such protective equipment becomes even more evident. Just as insulation materials have evolved to meet the growing demand of electrical systems, safety mats have become an indispensable part of workplace safety.

This ensures that those who work with electricity can do so in the safest conditions possible.

You can also see a complete guide to the different class electrical safety mats we have here.

Proper electrical insulation is vital for any electrical system, providing many benefits for the safe and efficient operation of electrical equipment. Here are just some of the key benefits it can offer:

One of the most important benefits of electrical insulation is its ability to help prevent electrical accidents. It acts as a grounding barrier between conductive parts, such as wires and circuit boards, to protect and insulate the employee against unintended or unexpected electrical current flows that can lead to severe injury or death.

All commercial and industrial electrical installations must meet workplace regulatory health and safety compliance. This compliance refers not only to the electrical system or switchboard but also to BSI standards for electrical safety matting used by employees or staff working on them.

Proper insulation also helps reduce equipment failure risk, often leading to costly downtime and repairs. It can also protect equipment and machinery from damage caused by moisture, dust, and other environmental factors.

Using proper electrical insulation also provides environmental benefits too. It can help reduce energy consumption and carbon emissions while also helping to improve the overall sustainability of electrical systems.

Any type of proper electrical insulator is some form of solid material which doesn’t conduct electricity when coming into contact with a live electrical current. The material’s properties and resistance value are such that it won’t allow that current to pass through it and endanger people or equipment. Here are some of the properties that many insulators have depending on materials:

Air permeability can benefit certain insulators like electrical safety matting that allow air to flow through its pores for additional insulating qualities.

Electrical insulators are made from non-conductive materials that don’t allow electricity to flow through them easily. The choice of material depends on the specific application and the conditions under which the insulation will be used. Electrical insulation falls into two categories: hard insulators (ceramic, glass, or plastic) or soft insulators (rubber or fabrics). Some common electrical insulators, and their uses, include:

Rubber is a popular material for electrical insulation due to its flexibility and durability. It’s often used in insulating wires and cables and insulating electrical equipment and machinery.

Plastic is lightweight, easy to work with, and provides good insulation properties. It’s often used as an alternative to rubber, though rubber is better for commercial or industrial applications.

Ceramic materials are excellent electrical insulators, resistant to high temperatures, chemicals, and mechanical stress. They’re often used in high-voltage applications.

Silicone is a synthetic rubber known for resisting high temperatures, chemicals, and moisture. It’s often used for high-voltage applications in extreme weather conditions.

So what is electrical insulation? Well, it’s essential and crucial to making any electrical system or switchboard safe, preventing accidents to employees in the workplace.

MatsDirect UK provides a wide range of safety products for electrical applications, from anti-static floor mats and electrical switchboard safety matting. Each ensures the safety of equipment and people and prevents workplace accidents when your staff or any third party works with live electrical equipment.

For more information on any safety floor matting, contact the team at MatsDirect UK today. Send us a message, call the team on 0161 797 6785, or email us at sales@matsdirect.co.uk, and we’ll ensure you have the correct electrical insulation specification for your application.

MatsDirect UK Ltd is fully ISO 9001:2015 (Quality Management System) accredited, which means we have demonstrated our ability to consistently provide products to the industry’s highest quality and standards.

Now, how’s that for peace of mind?

Website designed by Highpoint Media